Raytheon Aircraft

1996 – 1997

PROBLEM: The wing-to-fuselage and empennage-to-fuselage attachment points of conventional aircraft are heavy structures which use large mechanical fasteners such as bolts and rivets. Reduction of complexity and weight in these areas would be beneficial from the standpoints of maintenance (maintenance man-hours-per-flight-hour), supply infrastructure (spare parts and cataloging), and performance (reduced empty weight). For aircraft with major graphite/epoxy type composite components, the problem is more accute since durability and structural integrity tend to be compromised by the prsesence of holes in the component. The holes are necessary attachment points for mechanical fasteners.

SOLUTION: Use adhesives to bond the composite assemblies, thereby eliminating the need for mechanical fasteners.

DRAWBACK: Aircraft operate in extreme environmental conditions of moisture, heat, cold, and thermal/mechanical cycling. Adhesive bonds which are durable in such environments are costly, maintenance intensive (re-bonding), and not durable over the life of the aircraft.

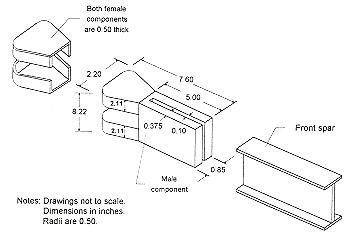

BETTER SOLUTION: Use the adjoining structure to maintain the relative position of components and transfer loads.

- Capped

- Tongue-In-Groove

- Dovetail

The new configurations are made of conventional materials, and were evaluated using Finite Element Methods.

FUTURE DIRECTION: Design graphite/epoxy type replacement attachment structures.